Juniper Innovations have found suppliers that bring you a new fresh look to GPS mapping.

Juniper Innovations review RFID software that can be used as a stand alone solution or integrated into a larger supply chain. So what practical uses can it be put to in a healthcare environment? (more…)

UK Statistics relating to road accidents involving goods vehicles make sober reading.

The case for using RFID within logistics and for industry is often cited as compelling. Is this really the case?

Intelligent Global Pooling Systems is a pallet rental company that supplies plastic pallets with embedded RFID tags. The claim is that “embedded RFID tags enable shippers and receivers to track shipments throughout the supply chain.”

Although the pallets are hired and you can expect them to come and go between warehouses, manufacturing centres and shipping points in open and closed loop environments, it is still possible to track pallet assets and stock using Juniper Innovations’ RFID and warehouse management system. Using a combination of RFID readers on dock doors and existing barcode readers for example, it is possible to track pallets and stock into and out of buildings. The warehouse management software is able to both track RFID tags on pallets plus link RFID tags to barcodes.

The Office for National Statistics shows that Q2 in 2010 saw an increase of 1.4 per cent, output per worker in the whole UK economy compared with the same quarter in 2009. IHS Global Insight said companies benefited from “having to adapt and streamline their operations to survive the recession with this leaving them leaner and fitter to compete.”

Juniper Innovations regularly discusses ideas to become leaner and fitter with manufacturing, logistics and construction organisations on how to best to:

Transport items, shipping units, distribution containers or whatever label you want to give them play an important role in logistics and manufacturing. Referring to items such as:

..they’re used to transport stock within a factory or warehouse, between buildings and to end markets and customers. Their significance is sometimes taken for granted however isn’t lost on Finance and Logistics Directors. They form a significant capital outlay and cause operational disruption when shortages occur. So picture the significance of a busy warehouse loading crates onto pallets, ready to be shipped onto a regional distribution centre before being distributed to a customer. As the pallets are loaded onto a truck the inventory is updated, recording which units are heading out, what units they precisely are, the truck they will be loaded to and where they are heading. There is no manual recording of information, no forms and no delay finding out the information as it is in real time. So can RFID really be used in this way today and what are the 5 tips for better RFID use?

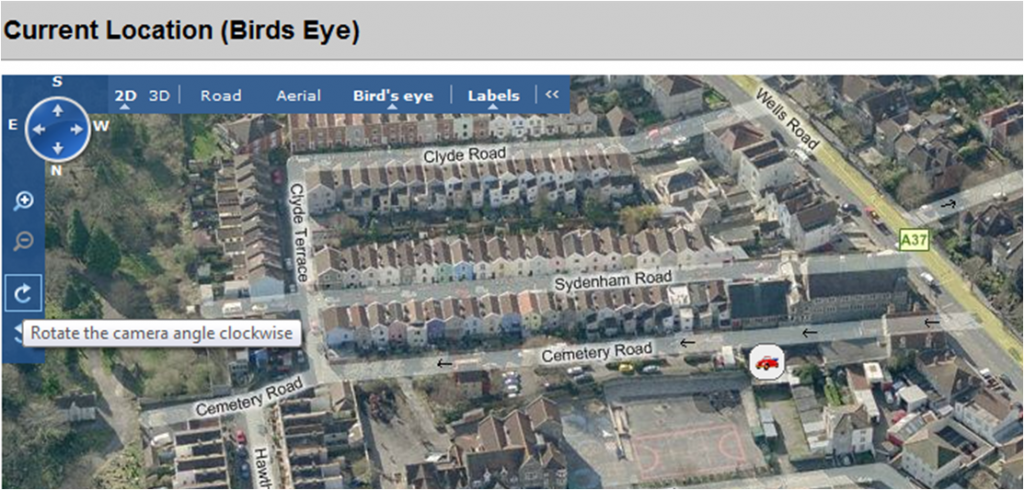

GPS technology is becoming more common and widespread in use. In the last week for example Google have announced the real-time tracking of airplane flights on Google Earth (based on data collected by Flightwise from the Federal Aviation Administration), Casio have announced a geotagging capability on a camera linking pictures and movements to GPS positions and points of interest, while the US military wants GPS capabilities in their Ipads (which stands for Improved Position and Azimuth Determining Systems, not their Apple gadgets). So for organisational and business use is all this GPS stuff gimmicky or can we get more use from the technology?

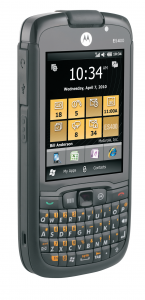

The new Motorola Global ES400 EDA was launched in June 2010 and is now being released in the UK.

The new Motorola Global ES400 EDA was launched in June 2010 and is now being released in the UK.

So what’s an EDA and why all the fuss?

In order to separate itself from a mobile phone and a PDA (personal digital assistant) an EDA, or enterprise digital assistant device is aimed at the business sector. Specifically it is for people working in for example warehouses, healthcare, retail, managing inventory or lone/mobile/field working. The EDA provides an alternative to a PDAs that is aimed at office and home users.

Choosing the right warehouse management system for your manual warehouse is an important job and rightly so, as it can bring significant benefits. From faster goods receipt and putaway, to aiding more accurate picking and packing, improvements in stock flow through to better stock control. Get the choice wrong however and it can lead to goods receipt delays, stock movement congestion, out of stocks in picking and late despatches. So what are 5 essential tips for making sure you pick the right system?